Wear Testing Fixture.

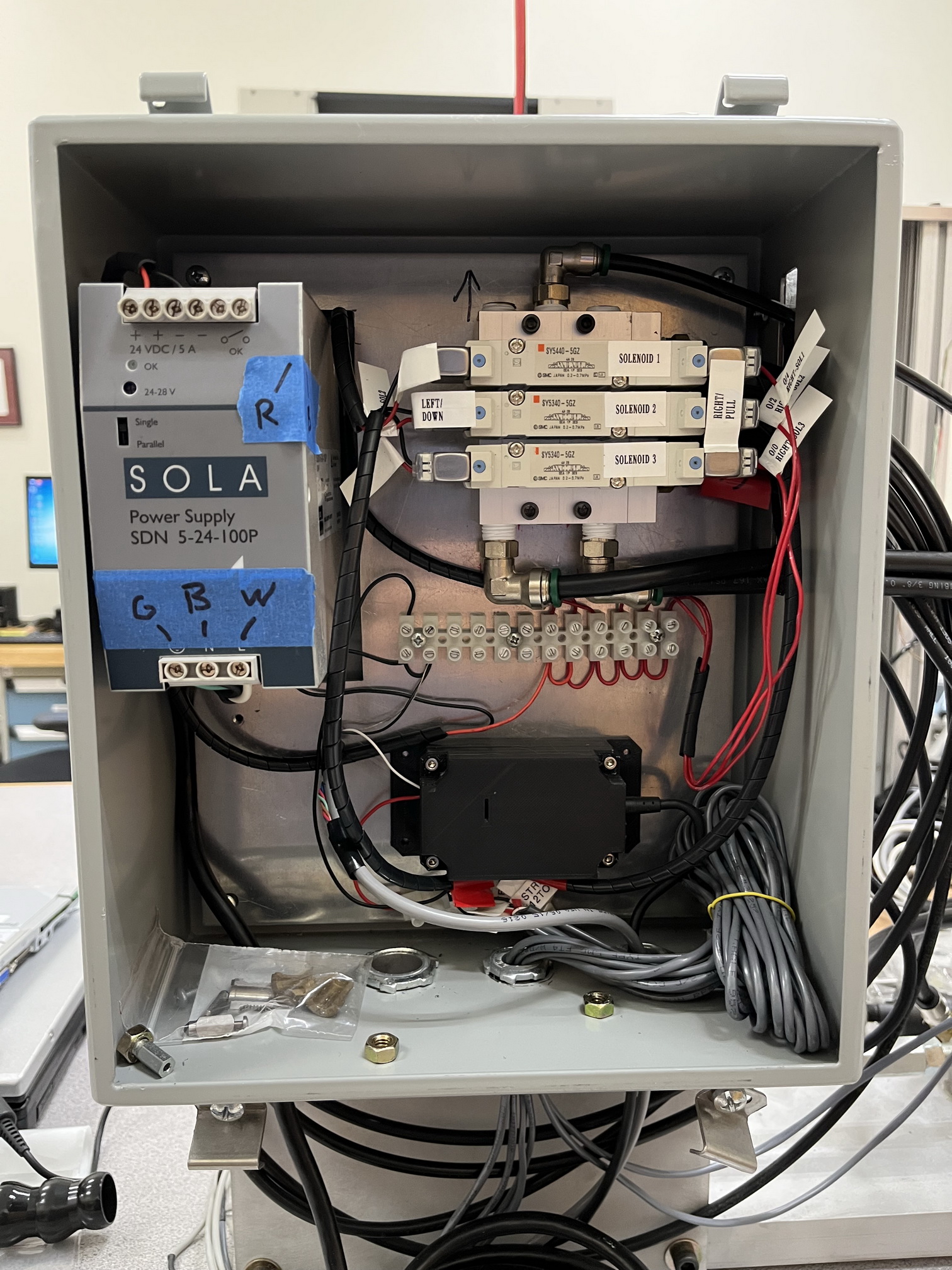

This test fixture was used to scrape across a sectioned portion of a carbeurator float valve to show indications of wear in the brass sleeve.

It was originally programmed with a plc controller, the goal was to be able to control the fixture using a DEWESoft Sirius Data Aquisition module while be able to record data from a load cell and a camera.

The PLC was removed.

The pneumatic relay wiring was tested manually to determine the states of control.

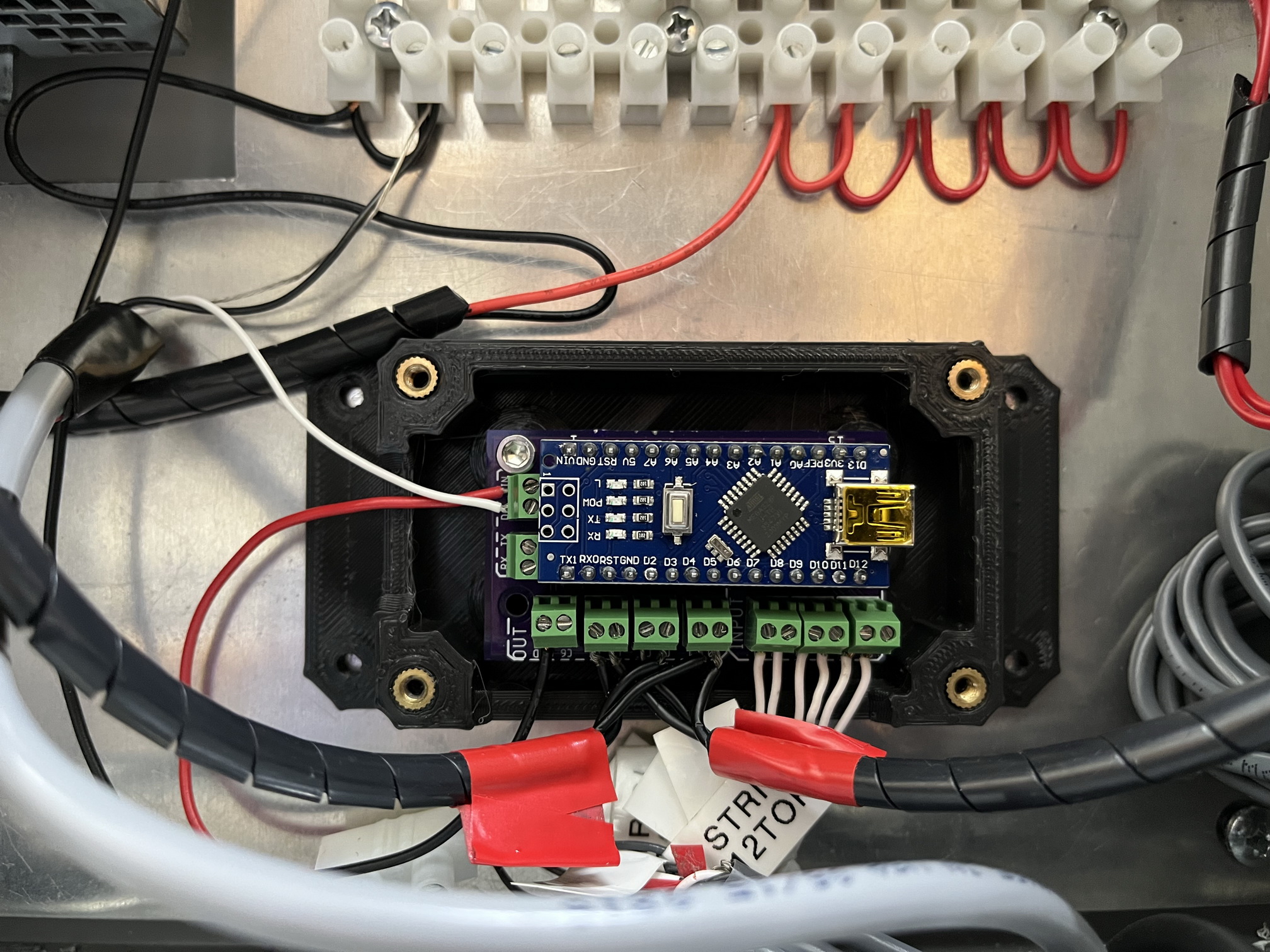

A arduino nano was chosen for the controller.

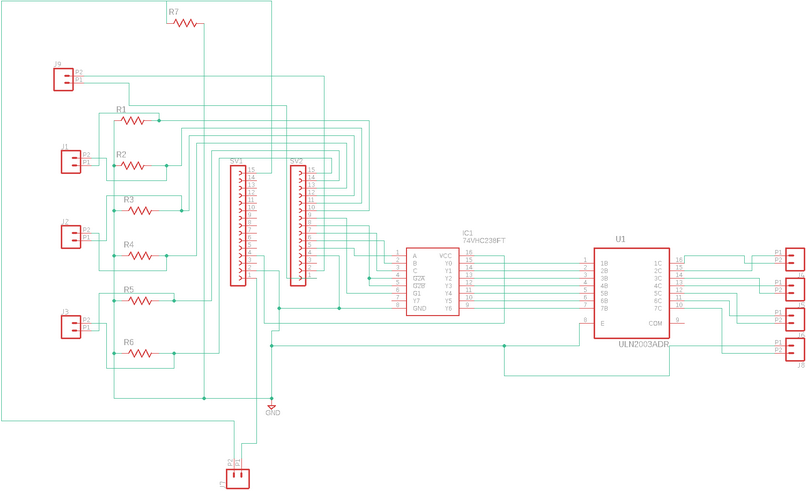

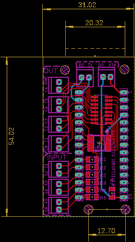

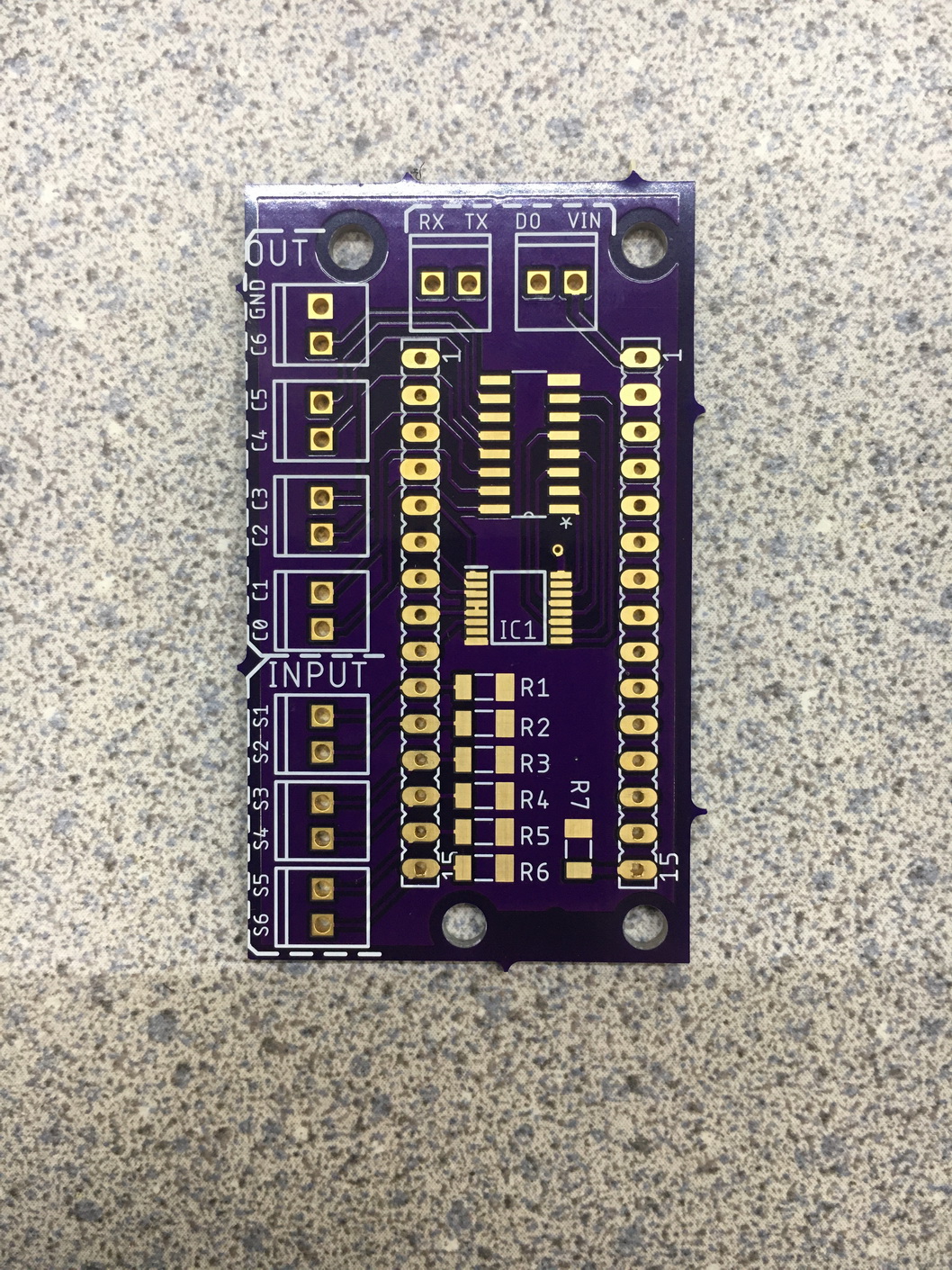

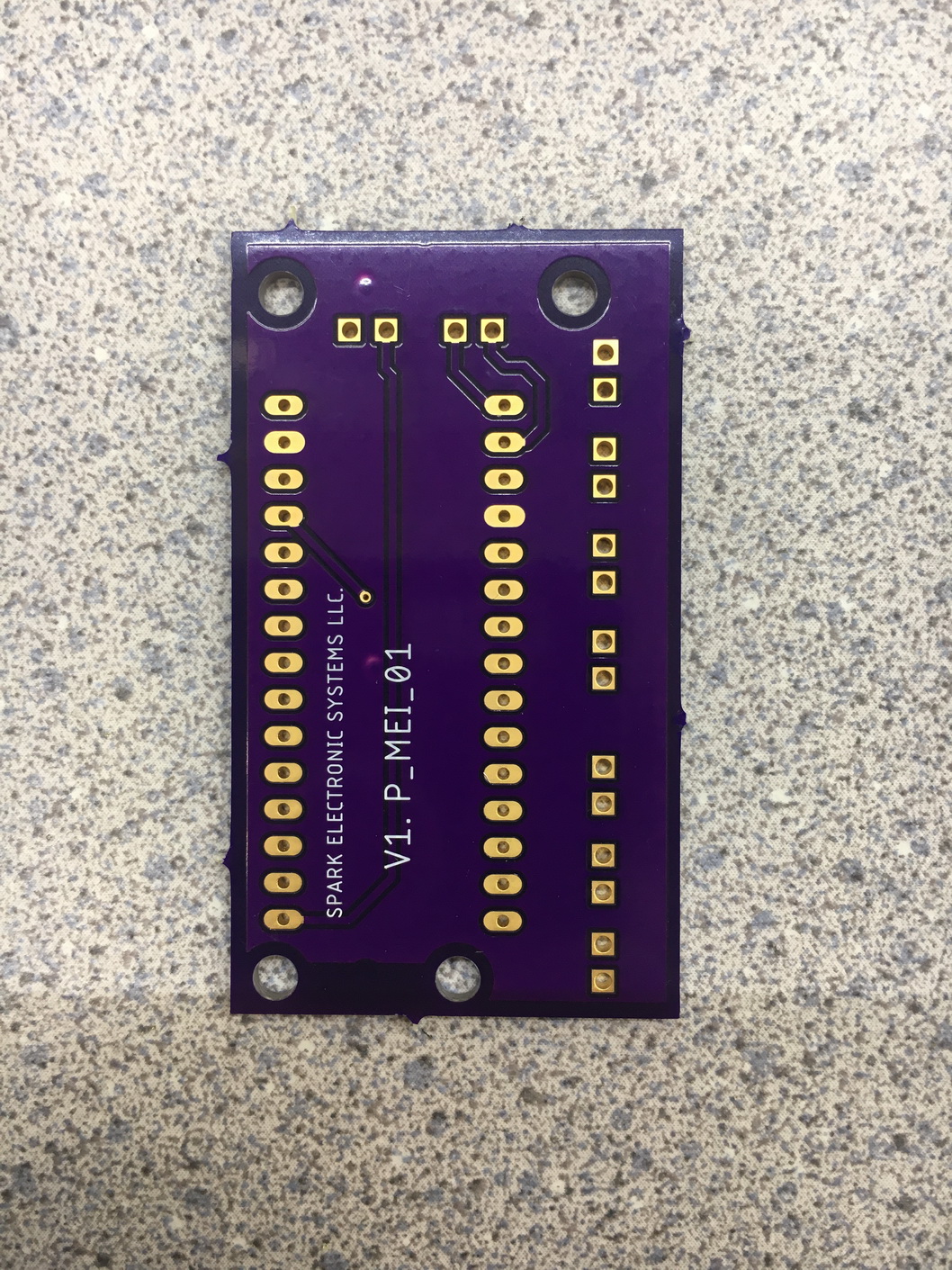

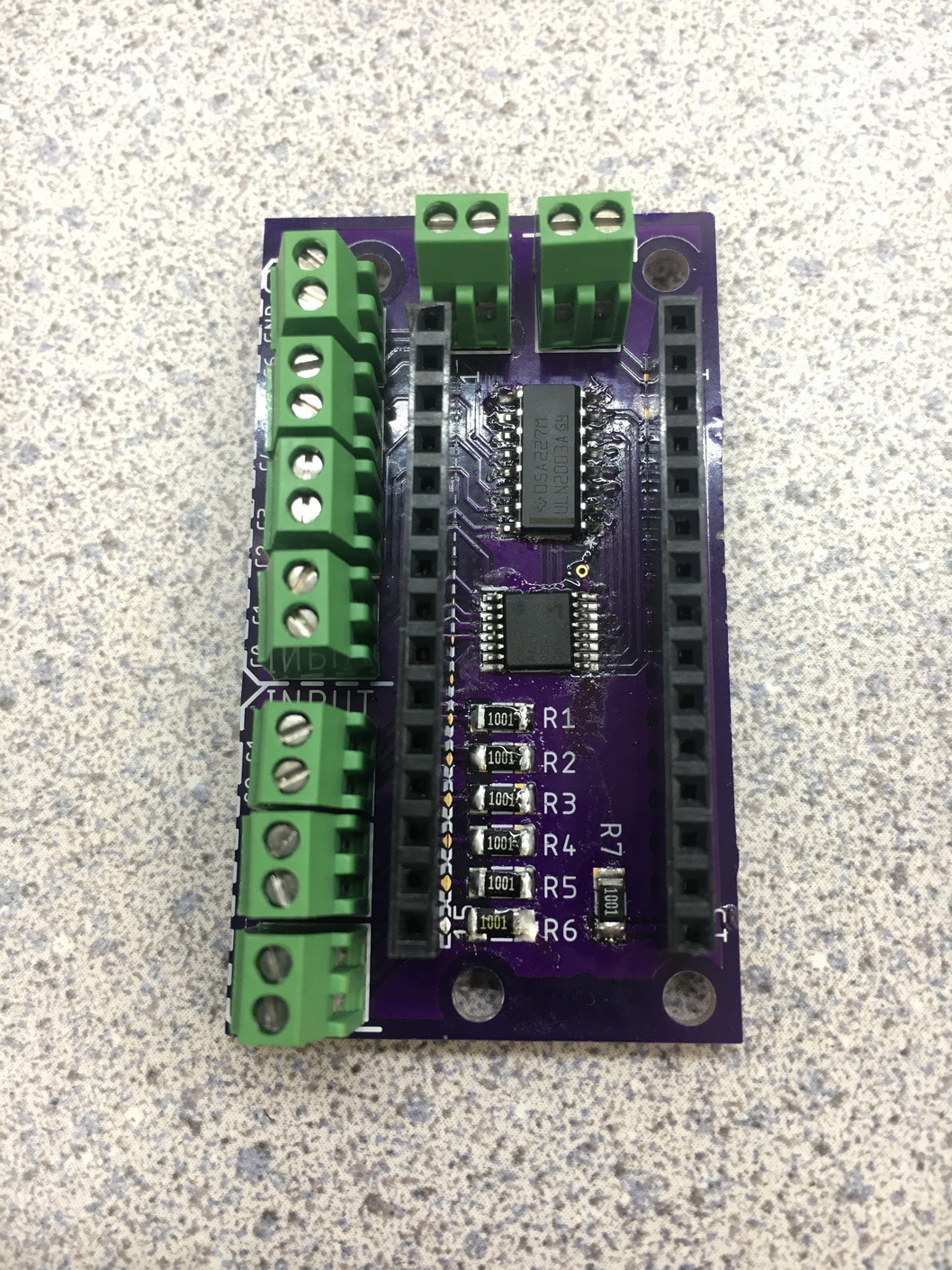

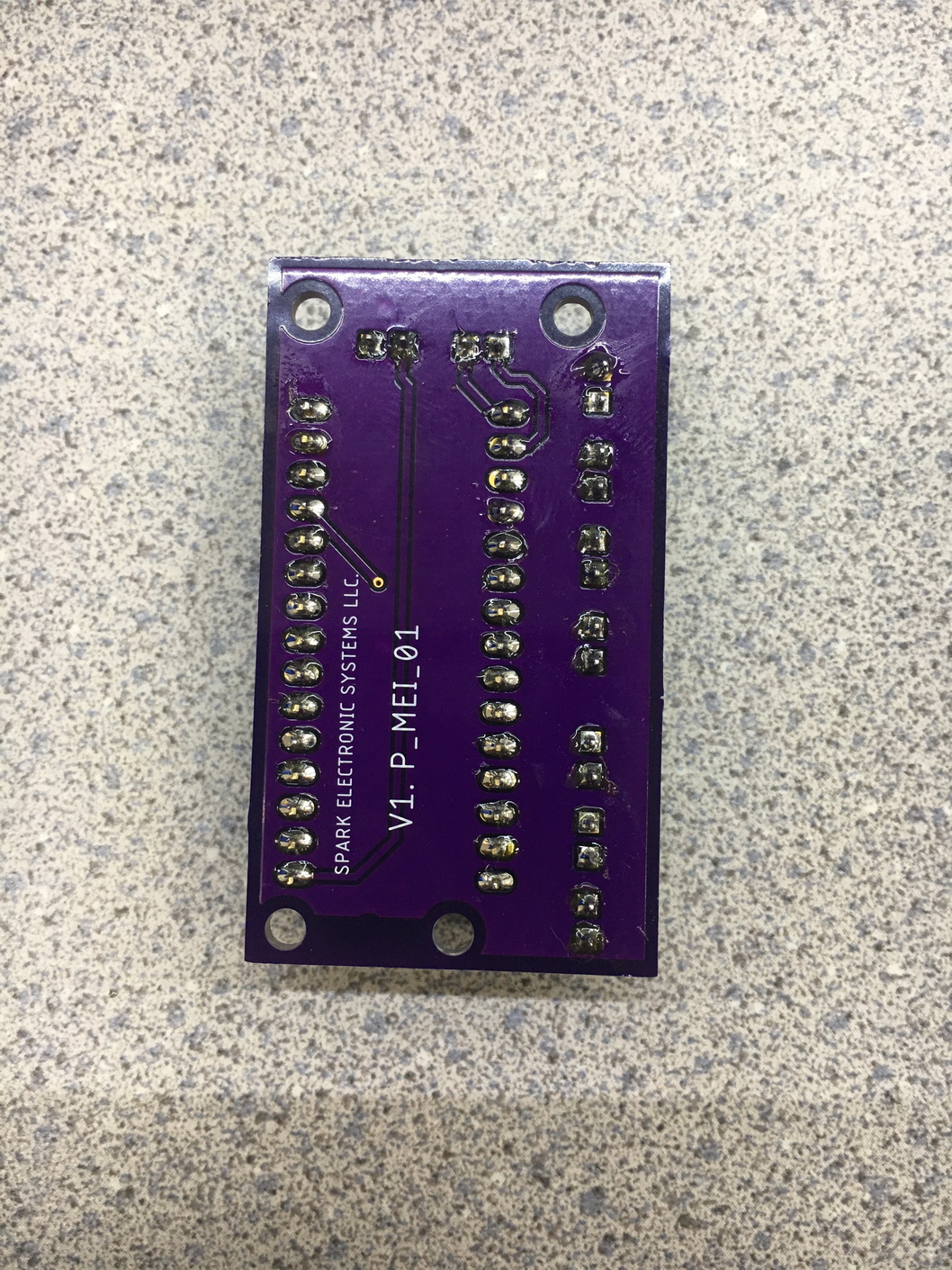

A custom PCB was designed to accommodate the inputs and outputs needed.

Since we are controlling the solenoids with a microcontroller an NPN Darlington pair chip "ULN2003A" was selected that features high-voltage outputs with common-cathode clamp diodes for switching inductive loads.

This was paired with a decoder to allow a smaller microcontroller chip to be used with fewer outputs.

The board was installed and tested.

The arduino nano was used to interpret the serial data from the DEWESoft module that was used to control the pneumatic solenoids.

With simple commands based on a MODBUS structure the entirety of the test fixture can now be controlled from a serial command line interface.